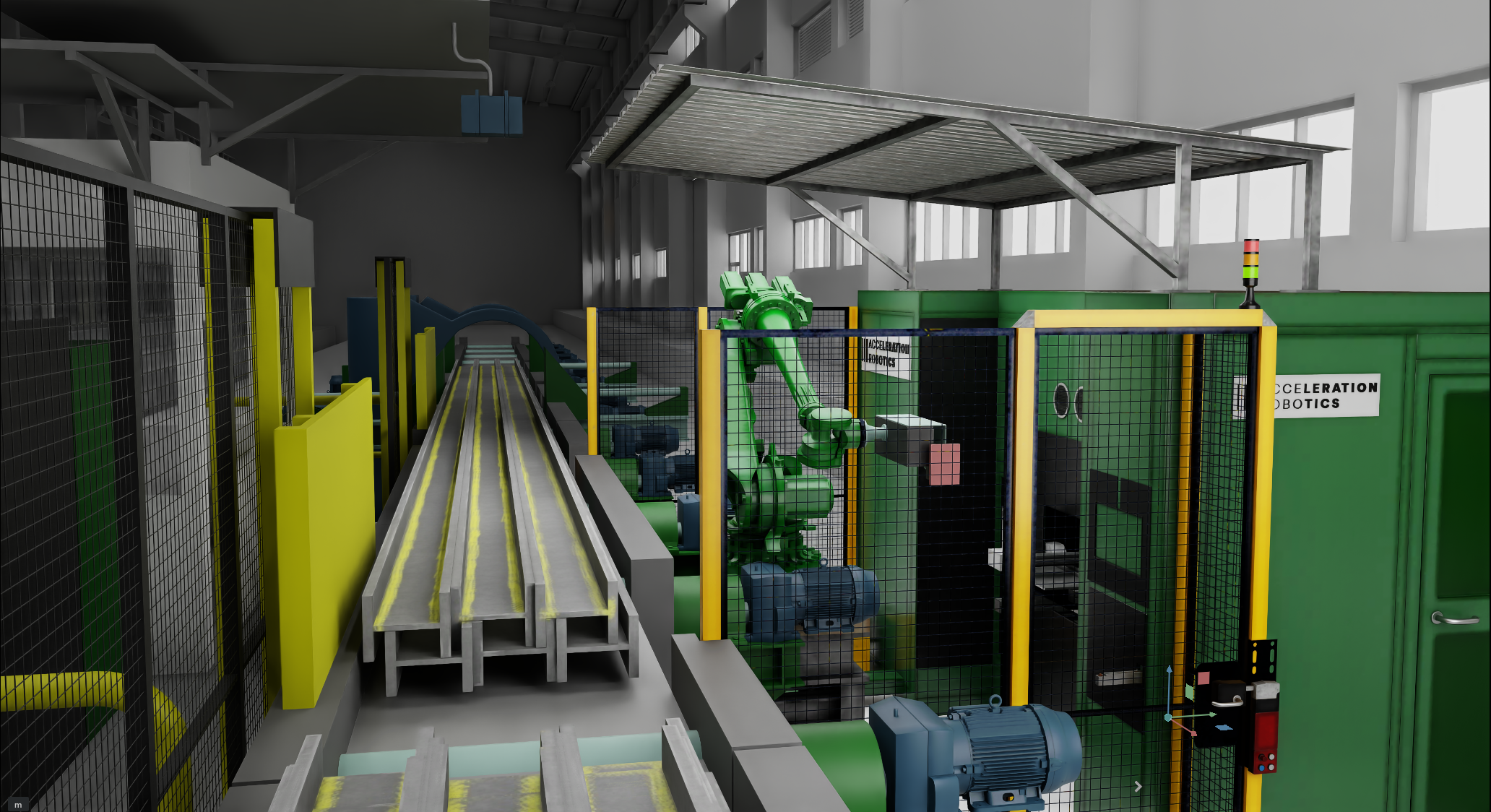

Accelerating metal part manufacturing with robots

Grupo Celsa, a leader in metal part manufacturing, faced challenges with slow, clunky robots powered by CPU-based vision proccesses, hindering production and quality control. Partnering with them, we accelerated their robot operations. By hardware accelerating their robotic vision pipelines by over 62x, we unlocked significant improvements in their robotic assemly processes. Robots can now operate faster, streamlining production.

Learn more

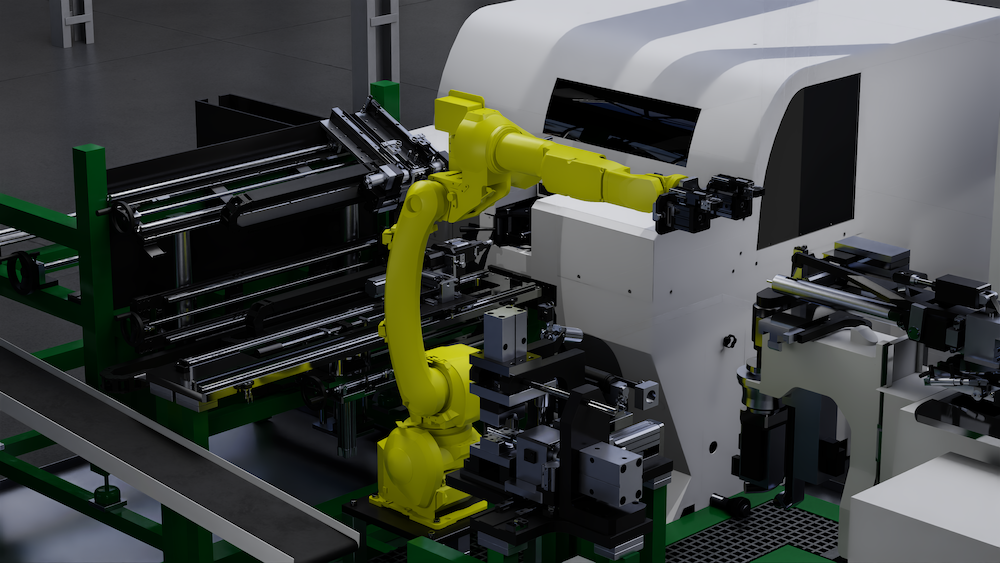

Accelerating industrial legacy robot manipulation

TEKNIA, an auto parts manufacturer, aimed to accelerate their robot production cycles. Through our collaboration, we first achieved a 16.21% increase in robot movement speed by optimizing trajectories, velocities, and accelerations. In a second stage, we reduced cycle time by 10.78% using double-manipulation techniques. These improvements empowered TEKNIA to produce an additional 800 units per day and over 20,000 units per month.

Learn more